બિસ્ફેનોલ CAS 80-05-7 માટે નવી ફેશન ડિઝાઇન, થર્મલ પેપરના સારા ભાવે ઉત્પાદન સાથે

અમારા ઉકેલો ગ્રાહકો દ્વારા વ્યાપકપણે ઓળખાય છે અને વિશ્વસનીય છે અને બિસ્ફેનોલ માટે નવી ફેશન ડિઝાઇન માટે સતત વિકસતી નાણાકીય અને સામાજિક જરૂરિયાતોને પૂર્ણ કરશે. CAS 80-05-7 થર્મલ પેપરના સારા ભાવ ઉત્પાદન સાથે, અમારી સાથે સહયોગ સ્થાપિત કરવા માટે બધા વિદેશી મિત્રો અને છૂટક વેપારીઓનું સ્વાગત છે. અમે તમારી માંગણીઓ પૂર્ણ કરવા માટે તમને સીધી, ઉચ્ચ ગુણવત્તાવાળી અને અસરકારક સેવાઓ આપીશું.

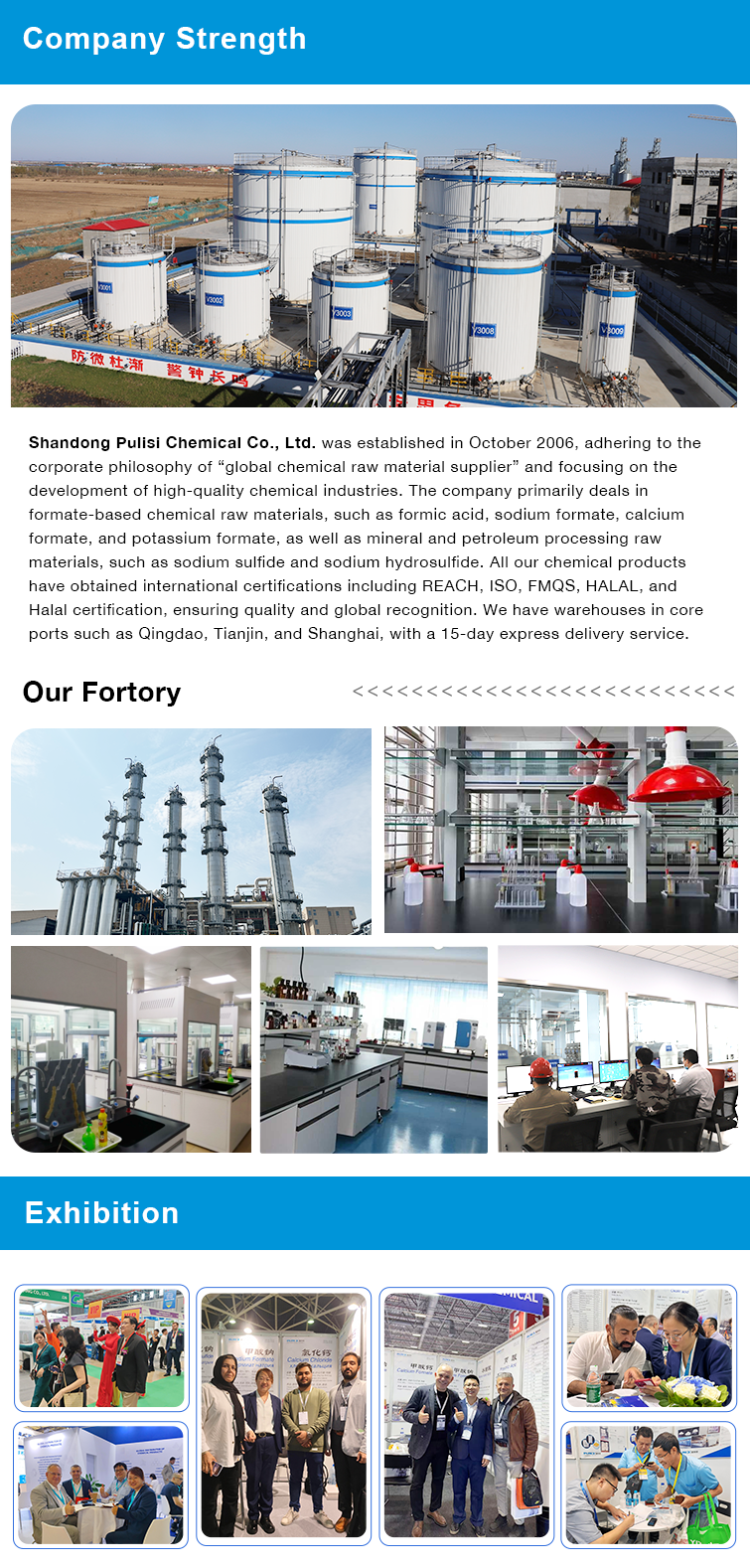

અમારા ઉકેલો ગ્રાહકો દ્વારા વ્યાપકપણે ઓળખાય છે અને વિશ્વસનીય છે અને સતત વિકાસશીલ નાણાકીય અને સામાજિક જરૂરિયાતોને પૂર્ણ કરશે, અમને આશા છે કે અમે બધા ગ્રાહકો સાથે લાંબા ગાળાના સહયોગ સ્થાપિત કરી શકીશું, અને આશા છે કે અમે સ્પર્ધાત્મકતામાં સુધારો કરી શકીશું અને ગ્રાહકો સાથે મળીને જીત-જીતની પરિસ્થિતિ પ્રાપ્ત કરી શકીશું. તમારી પાસે જે કંઈપણ હોવું જોઈએ તે માટે અમારો સંપર્ક કરવા માટે અમે વિશ્વભરના ગ્રાહકોનું નિષ્ઠાપૂર્વક સ્વાગત કરીએ છીએ! અમારા ફેક્ટરીની મુલાકાત લેવા માટે દેશ અને વિદેશના બધા ગ્રાહકોનું સ્વાગત છે. અમે તમારી સાથે જીત-જીત વ્યવસાયિક સંબંધો રાખવા અને વધુ સારા આવતીકાલનું નિર્માણ કરવાની આશા રાખીએ છીએ.

બિસ્ફેનોલ A ના સંગ્રહની સ્થિતિ "ઘટાડો અટકાવવા, સલામતી સુનિશ્ચિત કરવા અને પર્યાવરણીય પ્રભાવ ટાળવા" ના મુખ્ય ઉદ્દેશ્યોની આસપાસ ફરતી હોવી જોઈએ.

બિસ્ફેનોલ A (BPA) ના ઉપયોગો

બિસ્ફેનોલ A (BPA) એ પોલીકાર્બોનેટ, ઇપોક્સી રેઝિન અને ઉચ્ચ-તાપમાન પ્રતિરોધક પોલિએસ્ટરના સંશ્લેષણ માટે આવશ્યક કાચો માલ છે. તેનો ઉપયોગ પીવીસી સ્ટેબિલાઇઝર, પ્લાસ્ટિક એન્ટીઑકિસડન્ટ, યુવી શોષક, ફૂગનાશક વગેરે તરીકે પણ થાય છે.

એક બહુમુખી સંયોજન તરીકે, BPA નો ઉપયોગ ઇપોક્સી રેઝિન, પોલીકાર્બોનેટ, પોલિએસ્ટર રેઝિન, પોલીફેનાઇલીન ઈથર રેઝિન અને પોલિસલ્ફોન રેઝિનના ઉત્પાદનમાં વ્યાપકપણે થાય છે. વધુમાં, તે પ્લાસ્ટિકમાં એન્ટીઑકિસડન્ટ, યુવી શોષક, કૃષિ ફૂગનાશક અને રબરમાં વૃદ્ધત્વ વિરોધી એજન્ટ, પોલીવિનાઇલ ક્લોરાઇડ (PVC) માટે સ્ટેબિલાઇઝર તરીકે કામ કરે છે.

તેનો ઉપયોગ પેઇન્ટ અને શાહીમાં એન્ટીઑકિસડન્ટ અને પ્લાસ્ટિસાઇઝર તરીકે પણ થાય છે. કાર્બનિક સંશ્લેષણમાં, BPA ઇપોક્સી અને પોલીકાર્બોનેટ રેઝિન બનાવવા માટે મુખ્ય ઘટક તરીકે કાર્ય કરે છે, અને તે ઉચ્ચ-પરમાણુ કૃત્રિમ સંયોજનો, તેમજ વૃદ્ધત્વ વિરોધી એજન્ટો, પ્લાસ્ટિસાઇઝર્સ અને કૃષિ ફૂગનાશકો માટે મહત્વપૂર્ણ કાચા માલ તરીકે વ્યાપકપણે ઉપયોગમાં લેવાય છે.

૧. ડિલિવરી વિશ્વસનીયતા અને કાર્યકારી શ્રેષ્ઠતા

મુખ્ય વિશેષતાઓ:

ક્વિંગદાઓ, તિયાનજિન અને લોંગકોઉ પોર્ટ વેરહાઉસ ખાતે 1,000+ સાથે વ્યૂહાત્મક ઇન્વેન્ટરી હબ

મેટ્રિક ટન સ્ટોક ઉપલબ્ધ છે

15 દિવસમાં 68% ઓર્ડર ડિલિવર થયા; એક્સપ્રેસ લોજિસ્ટિક્સ દ્વારા તાત્કાલિક ઓર્ડરને પ્રાથમિકતા આપવામાં આવી

ચેનલ (૩૦% પ્રવેગક)

2. ગુણવત્તા અને નિયમનકારી પાલન

પ્રમાણપત્રો:

REACH, ISO 9001, અને FMQS ધોરણો હેઠળ ટ્રિપલ-પ્રમાણિત

વૈશ્વિક સ્વચ્છતા નિયમોનું પાલન; 100% કસ્ટમ્સ ક્લિયરન્સ સફળતા દર

રશિયન આયાત

૩. વ્યવહારિક સુરક્ષા માળખું

ચુકવણી ઉકેલો:

લવચીક શરતો: LC (દૃષ્ટિ/ટર્મ), TT (20% એડવાન્સ + શિપમેન્ટ પર 80%)

વિશિષ્ટ યોજનાઓ: દક્ષિણ અમેરિકન બજારો માટે 90-દિવસનું એલસી; મધ્ય પૂર્વ: 30%

ડિપોઝિટ + BL ચુકવણી

વિવાદ નિવારણ: ઓર્ડર-સંબંધિત સંઘર્ષો માટે 72-કલાકનો પ્રતિભાવ પ્રોટોકોલ

૪. ચપળ સપ્લાય ચેઇન ઇન્ફ્રાસ્ટ્રક્ચર

મલ્ટિમોડલ લોજિસ્ટિક્સ નેટવર્ક:

હવાઈ નૂર: થાઇલેન્ડમાં પ્રોપિયોનિક એસિડ શિપમેન્ટ માટે 3-દિવસની ડિલિવરી

રેલ પરિવહન: યુરેશિયન કોરિડોર દ્વારા રશિયા માટે સમર્પિત કેલ્શિયમ ફોર્મેટ રૂટ

ISO TANK સોલ્યુશન્સ: સીધા પ્રવાહી રાસાયણિક શિપમેન્ટ (દા.ત., પ્રોપિયોનિક એસિડને

ભારત)

પેકેજિંગ ઑપ્ટિમાઇઝેશન:

ફ્લેક્સિટેન્ક ટેકનોલોજી: ઇથિલિન ગ્લાયકોલ માટે 12% ખર્ચ ઘટાડો (પરંપરાગત ડ્રમ વિરુદ્ધ)

પેકેજિંગ)

બાંધકામ-ગ્રેડ કેલ્શિયમ ફોર્મેટ/સોડિયમ હાઇડ્રોસલ્ફાઇડ: ભેજ-પ્રતિરોધક 25 કિલો વણાયેલી પીપી બેગ

5. જોખમ ઘટાડા પ્રોટોકોલ

શરૂઆતથી અંત સુધી દૃશ્યતા:

કન્ટેનર શિપમેન્ટ માટે રીઅલ-ટાઇમ જીપીએસ ટ્રેકિંગ

ગંતવ્ય બંદરો પર તૃતીય-પક્ષ નિરીક્ષણ સેવાઓ (દા.ત., દક્ષિણ આફ્રિકામાં એસિટિક એસિડ શિપમેન્ટ)

વેચાણ પછીની ખાતરી:

રિપ્લેસમેન્ટ/રિફંડ વિકલ્પો સાથે 30-દિવસની ગુણવત્તા ગેરંટી

રીફર કન્ટેનર શિપમેન્ટ માટે મફત તાપમાન મોનિટરિંગ લોગર્સ

[પ્રાયોગિક પ્રક્રિયાઓ]

સાધન સ્થાપન

બિસ્ફેનોલ એક નમૂના ઉમેરો

① સૌપ્રથમ, સતત દબાણવાળા ફનલનો ઉપયોગ કરીને ફ્લાસ્કમાં ધીમે ધીમે 78% સલ્ફ્યુરિક એસિડનું 7 મિલી રેડો.

② પછી, વિભાજક ફનલનો ઉપયોગ કરીને 4 મિલી એસીટોન ઉમેરો, પ્રતિક્રિયા તાપમાન 35℃ થી વધુ ન રહે તે નિયંત્રિત કરો.

ગરમીની પ્રતિક્રિયા (નોંધ: એસીટોન ઉમેર્યા પછી, 35-40℃ તાપમાન જાળવી રાખો અને 2 કલાક માટે હલાવો)

બિસ્ફેનોલ એ પ્રોડક્ટ ટ્રીટમેન્ટ

ગાળણ: ફિલ્ટર કેકમાં અલગ કરો અને ગાળણ કરો.

ફિલ્ટર કેક: પુનઃસ્થાપન

ફિલ્ટરેટ: ટોલ્યુએન પુનઃપ્રાપ્ત કરવા માટે અલગ કરવું